Wetter drives recently, and with the windscreen just out of arms reach I'm decided to fit some de-mister vents in an attempt to move warm air over the inside of the screen.

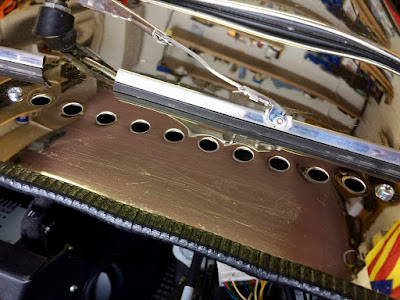

Same 10mm holes, and tools, used on the bonnet vents.

The choice was a plastic moulding - which looked too mass produced, a slot or a row of holes. The latter decided on since I know I can make it look tidy and it leaves plenty of scuttle behind to hold its strength.

The tape applied and marked up before moving the windscreen, these holes will sit tight against it's lower edge. Procedure is: pilot 3.2mm hole, widen to 6mm, punch to 10mm.

The crosshead bolts are just placeholders - they will be button head when I am finished.

The plenums had a number of options: I had purchased some along with the heater are too large, smaller 3d printed versions which were promising, but in the end decided to try something even simpler.

32mm PVC pipe cut diagonally lets me adjust the intake width to as wide as I like and avoids any need to join or make complex shapes, the flex hose should attach to the inboard end which will sit slightly proud of the surface. The air pressure will not be constant over the length - but this is a de-mister, not an engine intake.

Sits under the scuttle mounted with two bolts. The PVC piping bends and gives to the structure so no need for precise fitting of the curved shape. Biggest concern is ensuring any water ingress will avoid any electrics inside, so may add some foam packing around the opening and/or make sure the water drip route is harmlessly down the footwell sides.

It would have been easier to fit when the scuttle was off the car - potentially glueing a single half-sliced pipe across the whole width. The plan now is to use some flex hosing to plumb into the existing heater box.

Just waiting on some parts from ebay...